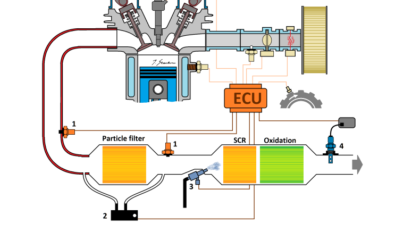

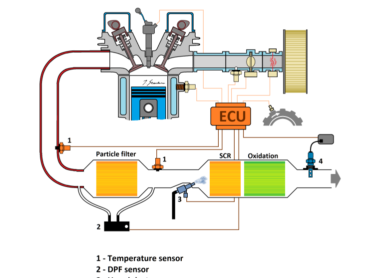

The high-pressure common rail system is a new concept of fuel injection system, which can improve the performance of diesel engines in all directions, making it a hot topic in the field of diesel engine research. Its composition mainly includes high-pressure pump, common rail pipe with pressure regulating valve, fuel injector with battery valve, electronic control unit and various sensors. The following is an introduction to the working principle and installation position of each sensor of the engine.

- Controller ECU characteristic parameters

Feature parameters:

① Working voltage: 24V (9~32);

② Working environment: – 30 ~ 105 degrees

③The ECU shell is required to be well insulated from the body;

The installation method on the engine is adopted to prevent the temperature of the engine body from being transmitted to the ECU, so a cooling box is installed between the ECU and the engine body to ensure that the ECU works at the allowable temperature.

- High pressure fuel pump

(Take the structure of CPN2.2 high pressure oil pump as an example)

- Inline double plunger high pressure oil pump

- Integrated fuel metering unit MeUN, which controls the rail pressure

- Integrated ZP5 gear oil delivery system

- The fuel filter is located on the pressure side of the gear pump

- lubricated with oil

- Drive speed ratio (deceleration): 6L/6M/6K: 1:2

- Theoretical oil supply rate of high pressure oil pump: 4.524cm3/rev

- Maximum allowable track music: 1600bar

- Spring rated speed: 1400r/min

- Counterclockwise rotation (viewed from drive end)

- Common rail pipe

1. Characteristic parameters:

Connector: three output terminals, respectively signal, ground, 5V power supply

Rated 30~160MPa

Maximum value: 160MPa

1. Electronic connector 2. Evaluation circuit 3. Film with sensor device 4. High pressure connector 5. Fixed thread

2、The sensor element on the sensor film converts the pressure change in the high-pressure pipeline into a voltage signal and sends it to the ECU. In case of damage, the pressure control valve is triggered by the set value through the emergency (backup) function

3. Features:

Integrated on the common rail pipe;

The maximum pressure is 1600bar;

4. Related control strategy: rail pressure closed-loop control

5. Failure modes and strategies:

- crankshaft/camshaft sensor

Function:

Accurately calculate the position of the crankshaft, used for the calculation of fuel injection timing, fuel injection quantity, and speed calculation

characteristic:

Variable reluctance type, installed on the gear chamber;

Air gap: 0.5mm—1.5mm;

Static resistance value: 860 ohms

Working environment: -40 degrees – 120 degrees;

- Signal plate design:

Number of teeth (Z is the number of cylinders);

Crankshaft speed signal plate: 58 teeth;

Camshaft signal plate: Z +1;

- Crankshaft (NE) sensor installation position

1. The crankshaft sensor is installed on the gear chamber through the bracket, and the signal is collected through the concave teeth on the shock absorber;

2. The distance between the lower end surface of the speed sensor and the signal tooth surface is: 1±0.5mm

- Camshaft (G) sensor installation position

1. The camshaft sensor is installed on the gear chamber, and the signal is collected through the convex teeth on the signal plate;

2. The distance between the lower end surface of the speed sensor and the signal tooth surface is: 1±0.5mm

- Crankshaft/camshaft sensor

Signal disc phase relationship:

When the first cylinder ends the compression stroke at compresses the top dead center, the camshaft phase sensor should indicate to the position of 81 degrees behind the multi-teeth of the signal plate; the crankshaft sensor should indicate to the 36th tooth after the missing tooth of the signal plate;

For example, the six-cylinder engine (CP2.2/CP3.3 oil pump is applicable: as shown in the figure, when the engine is at the compression top dead center of the first cylinder, the camshaft sensor should indicate 81° behind the multi-tooth of the camshaft signal plate (cam rotation angle ), the crankshaft sensor should indicate the position of the 36th tooth after the missing tooth of the crankshaft signal plate (the counting direction is against the engine rotation direction). If it is inconvenient to confirm the compression top dead center of the first cylinder, you can first follow the following method Preliminary judgment: When the camshaft sensor is aligned with the multi-teeth of the cam signal plate, the crankshaft sensor should be aligned with the 9th tooth after the missing tooth of the crankshaft signal plate, and vice versa. Note: this method can only determine the camshaft The relationship between the camshaft and the crankshaft signal disk and the top dead center of the engine cannot be determined.

- Boost pressure and temperature sensor

Function: It allows to calculate the Air-Fuel ratio (AFR) by measuring the pressure inside intake manifold and the temperature of the intake air. Based on that an air volume is calculated by ECU.

Features: integrated temperature sensor and pressure sensor;

Working temperature range: -40~130℃;

Working pressure range: 50~400kpa;

- Oil pressure temperature sensor

The oil pressure temperature sensor can detect the oil pressure and oil temperature at the same time, and its principle is the same as that of the intake air pressure temperature sensor.

- Cooling water temperature sensor

Principle: After the temperature signal is converted into a voltage signal, it is sent to the ECU for comparison, and the action of the actuator is controlled after the operation;

Function: to measure the cooling water temperature, used for cold start, calculation of target idle speed, correction of fuel injection advance angle, maximum power protection, etc.;

characteristic:

①Thermistor sensor

②Working voltage: 5±0.15V

③Working environment: – 40~140℃

Static resistance: 2500±6% ohms;

Fault performance: Insufficient power, speed limited within 1700 rpm;

- Fuel metering valve

Function:Control the amount of fuel entering the high-pressure fuel pump, thereby controlling the rail pressure

characteristic:

1. Coil resistance: 26~ 315 ohms

2. Maximum working current: 1.8A

3.Working current at rapid speed: 1380~1430mA

4. Duty cycle: 0~50%

5. Integrated on the high-pressure oil pump, disassembly is not allowed

- Once the fuel metering valve fails, the pressure relief valve on the common rail pipe will be forced to stay open.

- Once the fuel metering valve fails, the entire high-pressure fuel pump must be replaced, and it is not allowed to replace the fuel metering valve by itself.

- Throttle Position Sensor

Function: Send the driver’s intention to the ECU;

Features:

a. Dual signal output;

b. 6 output terminals

c. OUT1 voltage: OUT2 voltage = 2: 1

d. Working temperature range: -40~85℃

Related control strategies: torque limit; idle speed control; deceleration fuel cut control; Limp home control;

Best Growth Performance Sensing business focus on provide high quality sensor for Heavy Vehicle & 0ff Road (HVOR) and automotive markets.

Our products can be used for everything from improving performance and safety to helping the environment by reducing emissions. Our sensors and switches detect pressure, camshaft , crankshaft ,temperature, air flow, speed, position and provide on/off controls used in automotive and heavy duty applications.

HVOR – We committed to the global market for Agriculture and Construction vehicles and equipment. In addition we have been serving the global Truck market for many years.

AUTOMOTIVE – ln vehicles,our components are found in engines, fuel emission , air conditioning systems, power steering systems, and braking and suspension systems.

#ECU #Highpressurefuelpump #Commonrailpipe #Commonrailpressuresensor #crankshaftsensor #camshaftsensor #Boostpressure #temperaturesensor #Oilpressuretemperaturesensor #Coolingwatertemperaturesensor #Fuelmeteringvalve #throttlepositionsensor #HVOR #Failuremodes #resolutionstrategies #Function #Features #Enginesensors