The exhaust system of modern Diesel engines has become an extremely complex device.

The necessity to reduce the harmful components from the exhaust gases, forced by law, became the reason for this.

During the combustion proces of Diesel fuel, with local oxygen deficiency, soot particles with a size not exceeding 10 µm, known as PM10 or also as “TSP” (Total Suspended Particulates), are formed. Research shows that the risk of developing cancer of the human respiratory system increases from 20% to 50% in people who are constantly in the environment of working with compression ignition engines. In cities, this risk applies not only to people working directly on the engines, but also to people who come into contact with urban traffic.

There are two ways to reduce PM10 in the exhaust gas. One is the engine design changes and better control of the combustion process in the engine and the reduction of sulfur contained in the fuel, which allows the reduction of PM10 by 5-10%. The second, much more effective method is the capture of PM10 directly from the engine exhaust gases. Diesel Particle Filters are used for this purpose. The first passenger car equipped with such a filter was the Peugeot 607 back in 2000.

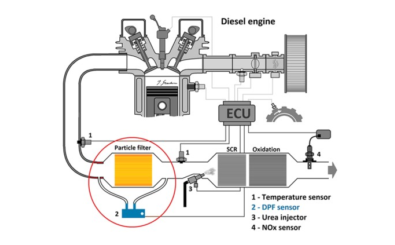

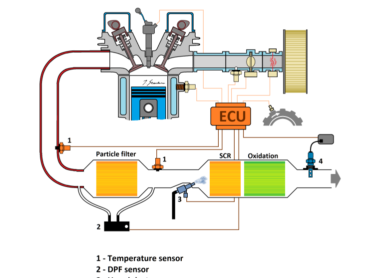

In the filter, particles are collected until the filter is fully saturated. This condition occurs after about 700 km. The on-board electronics of the engine is informed about this state by the DPF sensor, which measures the pressure difference upstream and downstream of the DPF. When this condition is achieved, the filter must be cleaned. For the soot to burn, the exhaust gas temperature must be higher than soot ignition temperature, i.e. around 550 ° C. The problem with everyday traffic is that the exhaust gas does not always achieve the sufficient temperature. In order to raise the exhaust gas temperature above the soot flash point, additional fuel is injected into the cylinder at the end of the combustion stroke, which is burned in the exhaust system, raising the exhaust gas temperature to the level in which the PM10 burns out. During this process, intense white smoke consisting of ashes is emitted from the exhaust system after the soot particles from the DPF are burned.

In the ADAC test covering over 80,000 km, the Peugeot 607 – the first passenger car to be fitted with a particle filter – emitted only 0.001 g of particles per kilometer. It was only 4% of the limit value allowed by the Euro 4 emission standard. Quoting the ADAC – it can be concluded that passenger cars with particle filters practically do not produce soot particles.

We offer a wide range of products and technologies dedicated for Diesel emission systems, Including NOx sensors, urea pumps, urea metering valves, urea nozzles, exhaust temperature sensors, DPF sensors, pedal sensors, urea accessoriess, urea filters, testing equipments, as Stand-along solutions or Emission Control components, for On-Road, Off-Road vehicles as well as for Industrial applications.

High quality products bring good protection to customers, which can bring you more business opportunities.www.best-growth.com. If you are interested in products do not hesitate to contact us,let us cooperate and win-win!

Msc. Eng. Jacek Gembara

#EMISSIOCONTROLSYSTEMACCESSORIES #NOxsensor #ureapump #ureameteringvalve #ureanozzles #exhausttemperaturesensor #dpfsensor #pedalsensor #ureaaccessories #ureafilter #testingequipment