The NOx sensor for vehicles is an important exhaust gas measurement tool. It cooperates with the truck after-treatment system to ensure that the vehicle exhaust emissions meet the standards. The engines of the National IV and National V stages generally have only one NOx sensor installed downstream of the catalyst; the National VI and Euro VI stages have at least two NOx sensors, one upstream and one downstream of the catalyst. A proper location of the NOx sensor should avoid the lowest areas of the catalytic converter. The following are common fault codes and detection methods for NOx sensors:

NOx Sensor Interface Definition

There are three common kinds of NOx sensors on the market:

- Fault code: U1307

Fault phenomenon: NOx sensor and ECU communication failure: NOx sensor communication timeout.

solution:

(1) Check whether the connector of the NOx sensor is firmly connected, if the connector of the sensor itself is damaged, please replace the sensor.

(2)Turn the ignition key in the OFF position, unplug the NOx sensor connector, and conduct a visual inspection. If the sensor pins are bent or there are traces of water entering the sensor terminal connector, as shown in the figure below, please replace the sensor.

(3) Turn the ignition key in the ON position, without starting the engine, use the AS-202 automotive circuit tester to measure the voltage between the sensor pair wiring harness end pin “e” and pin “d” (see Figure 1 and 2 for pin definition), The target value is 16V ~ 36V, if it is not within the range, please check the sensor power supply circuit and battery voltage.

(4) Turn the ignition key in the OFF position, measure the resistance between pin “b” and pin “c” of the wiring harness end of the NOx sensor pair, and the target value is about 60Ω. If there is any abnormality, it can be determined that the sensor pair wiring harness is faulty.

(5) Turn the ignition key in the OFF position, measure the resistance of the NOx sensor pair wiring harness terminal pin “b”, pin “c” to pin “d” respectively, the two resistance target values should be both greater than 1MΩ, if there is any abnormality, it can be determined that the sensor pair has connection Harness failure.

(6) Turn the ignition key in the OFF position, measure whether the sensor is connected to the wiring harness end pin “b” and the X1-42 of the engine ECU vehicle end, and whether the pin “c” is connected to the X1-43. If there is no conductivity, it can be assessed as pair wiring harness failure.

(7) Turn the ignition key in the OFF position, measure the resistance of the NOx sensor to the wiring harness terminal pin “b”, pin “c” and pin “e” respectively, the two resistance target values are both greater than 1MΩ, if it is less than 1MΩ, the sensor can be assessed as faulty pair wiring harness.

(8) Turn the ignition key in the OFF position, measure the resistance between pin 3 and pin 4 of the sensor end, the target value is 26.xn--6k-fcc ~ 29.xn--4k-fcc, if it is not within the range, please replace the sensor.

- P2200

Fault phenomenon: NOx sensor power supply status: NOX sensor power supply is not in the normal range.

solution:

(1) Turn the ignition key in the ON position, without starting the engine, use an AS-202 multimeter to measure the voltage between the pin “e” and pin “d” of the sensor pair wiring harness end. The target value is 16V ~ 36V. If it is not within the range, please check sensor power supply line and battery voltage. Same as solution (3) of U1307.

(2)Turn the ignition key in the OFF position, unplug the NOx sensor connector, and conduct a visual inspection. If the sensor pins are bent or there is water or moisture in the sensor terminal connector, replace the sensor. Same solution as U1307.

- P2201

Fault phenomenon: NOx sensor oxygen signal status: NOx sensor oxygen signal failure.

Solution:If the fault code U1307 does not appear when this fault code occurs, the NOx sensor can be replaced directly. If the fault code U1307 occurs at the same time, refer to the processing method of the fault code U1307. If there is no problem after checking (1) to (8) of U1307, replace the sensor.

- P2204

Fault phenomenon: NOx sensor signal status: NOx sensor concentration signal failure.

Solution: If the fault code U1307 does not appear when this fault code occurs, the NOx sensor can be replaced directly. If the fault code U1307 occurs at the same time, refer to the processing method of the fault code U1307. If there is no problem after checking (1) to (8) of U1307, replace the sensor.

- P2209

Fault phenomenon: NOx sensor operating temperature Status: NOx sensor does not reach the operating temperature.

Solution: If the fault code U1307 does not appear when this fault code occurs, the NOx sensor can be replaced directly. If the fault code U1307 occurs at the same time, refer to the processing method of the fault code U1307. If there is no problem after checking (1) to (8) of U1307, replace the sensor.

- P1D21

Symptom: NOx sensor removed

Solution: Check whether the sensor probe is installed in place, and check whether the wiring harness of the sensor itself is damaged.

- P0050

Symptom: NOx sensor CAN signal reception timed out

Solution:

(1)Check whether the connector of the NOx sensor is inserted firmly. If the connector of the sensor itself is damaged, please replace the sensor.

(2)Turn the ignition key in the OFF position, unplug the NOx sensor connector, and conduct a visual inspection. If the sensor pin is bent or there is water or moisture in the sensor terminal connector, as shown in the figure below, please replace the sensor.

(3)Turn the ignition key in the ON position, without starting the engine, use the AS-202 automotive circuit tester to measure the voltage between pin e and pin d of the wiring harness end of the sensor pair (see attached drawings 1 and 2 for the pin definition), and the target value It is 16V~36V, if it is not within the range, please check the sensor power supply circuit and battery voltage.

(4)Turn the ignition key in the OFF position, measure the resistance between pin “b” and “c” of the wiring harness end of the NOx sensor pair, and the target value is about 60Ω. If there is any abnormality, it can be determined that the sensor pair wiring harness is faulty.

(5)Turn the ignition key in the OFF position, measure the resistance of the NOx sensor pair from pin “b”, pin “c” to pin “d” of the wiring harness end respectively, the target resistance values of both are greater than 1MΩ, if there is any abnormality, it can be judged that the sensor pair is Faulty wiring harness.

(6)Turn the ignition key in the OFF position, measure whether the sensor pair wiring harness end pin b is connected to the K54 on the vehicle end of the engine ECU, and whether the pin c is connected to K76. If there is no conductivity, it can be determined that the sensor pair wiring harness is faulty.

(7)Turn the ignition key in the OFF position, measure the resistance of the NOx sensor to the wiring harness terminal pin b, pin c and pin e respectively, the two resistance target values are both greater than 1MΩ, if it is less than 1MΩ, the sensor can be judged Faulty pair wiring harness.

(8)Turn the ignition key in the OFF position, measure the resistance between pin 3 and pin 4 of the sensor end, the target value is 26.xn--6k-fcc ~ 29.xn--4k-fcc, if it is not within the range, please replace the sensor.

- P017E

Fault phenomenon: The power supply voltage of NOx sensor is too high

Solution:

(1) Turn the ignition key in the ON position, without starting the engine, use the AS-202 automotive circuit tester to measure the voltage between pin e and pin d at the wiring harness end of the sensor pair. The target value is 16V~36V. If it is not within the range, please check the sensor power supply circuit and battery voltage. Same as P0050 solution(3).

(2)Turn the ignition key in the OFF position, unplug the NOx sensor connector, and conduct a visual inspection. If the sensor pin is bent or there is water in the sensor terminal connector, replace the sensor. Same as P0050 solution (2).

- P018C

Symptom: NOx sensor preparation timed out

Solution: replace the NOx sensor

- P018D

Fault phenomenon: The measured value of the NOx sensor is too high

Solution: replace the NOx sensor

- P018E

Fault phenomenon: The measured value of the NOx sensor is too low

Solution: replace the NOx sensor

- P018F

Fault phenomenon: The internal circuit of the NOx sensor is open

Solution: replace the NOx sensor

- P0190

Fault phenomenon: short circuit in the internal circuit of the NOx sensor

Solution: replace the NOx sensor

- P01FC

Fault phenomenon: wrong value detected

Solution: Check whether the sensor probe is installed in place, and check the wiring harness of the sensor for damage.

- P01FD

Fault phenomenon: wrong value detected

Solution: Check whether the sensor probe is installed in place, and check the wiring harness of the sensor for damage.

- P01FE

Fault phenomenon:wrong value detected

Solution: Check whether the sensor probe is installed in place, and check the wiring harness of the sensor for damage.

- P01FF

Fault phenomenon: wrong value detected

Solution: Check whether the sensor probe is installed in place, and check the wiring harness of the sensor for damage.

Note: 1. When the fault code does not match the fault name, the fault code shall prevail.

2. If the above fault code is not read, it is not recommended to replace the NOx sensor.

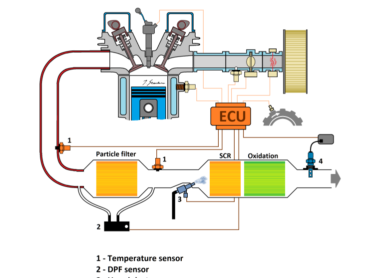

2. Topology diagram of NOx sensor

CAN communication is used between the NOX sensor and the ECU, and the CAN network topology diagram of the vehicle communication is shown in Figure 3. The meter and the engine ECU are two terminals of the CAN bus, each with a 120Ω resistor inside, and the NOX sensor is hung on the bus without a terminal resistor.

3. Various parameters of the NOx sensor

Working voltage: (16~36)V

Working current: 0.6A

Starting peak current: 12A

Power supply: 20W

NOX output range: 0~3000ppm

Operating environment temperature: (-40~105) ℃

Probe working temperature range: (200~800) ℃

Probe tightening torque: (50±10) Nm

Harness length of probe and processing unit: (908±8) mm

#NOxsensorfaultcodes #NOxsensorFaultDetectionMethod #NOxsensor #VariousparametersoftheNOxsensor #TopologydiagramofNOxsensor #NOxsensorpindefinition #NOxSensorInterfaceDefinition #FaultCodesandFaultDetectionMethods