10 years experience in NOxsensor

production

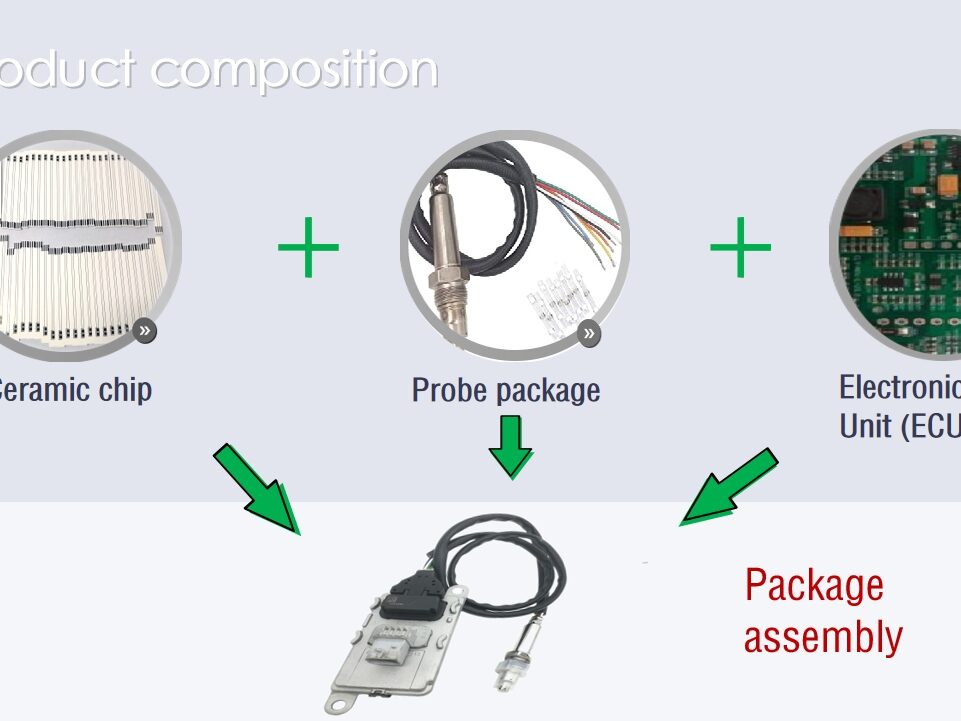

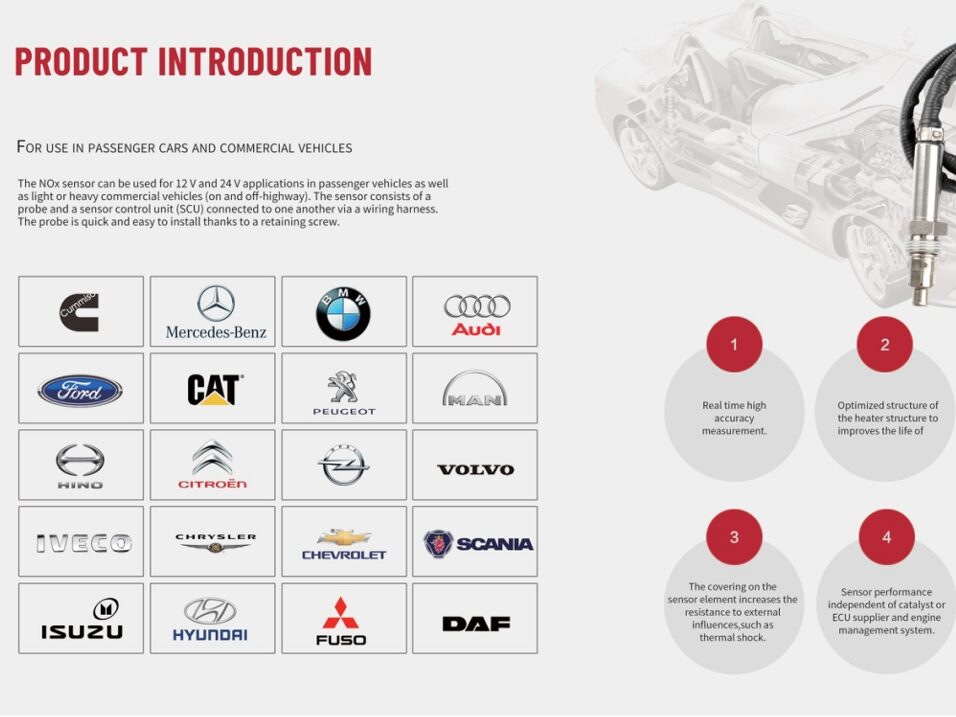

The intelligent nitrogen and oxygen sensor consists of a ceramic chip and an electronic control unit. It is used to measure the exhaust of gasoline or diesel engines.

The concentration of nitrogen oxides in the air.

The intelligent nitrogen and oxygen sensor can measure the NOx concentration, air-fuel ratio (A/F) and oxygen in the exhaust gas of gasoline or diesel engines.

gas concentration three parameters. Intelligent nitrogen and oxygen sensors are mainly used for: lean combustion engines, diesel engines, and online diagnosis.

Quality meets all standards★Reliability tests meet the standard GB/5772-2010, GB17691-2005, JB/T51184-2000

★ Efficiency tests meet the standard EPS200 , EPS708 , EPS815

★Products meet the requirements of Bosch, Denso and Germany mainland

R&D STRENGTHBG has more than 50 senior technical R&D personnel, more than 10 external experts and technical advisory teams. Many of them have worked in large and medium-sized enterprises and scientific research units.

TEAMThey have rich professional and technical work experience and high-quality equipment adjustment ability. This is a research- oriented and application-oriented innovative team.

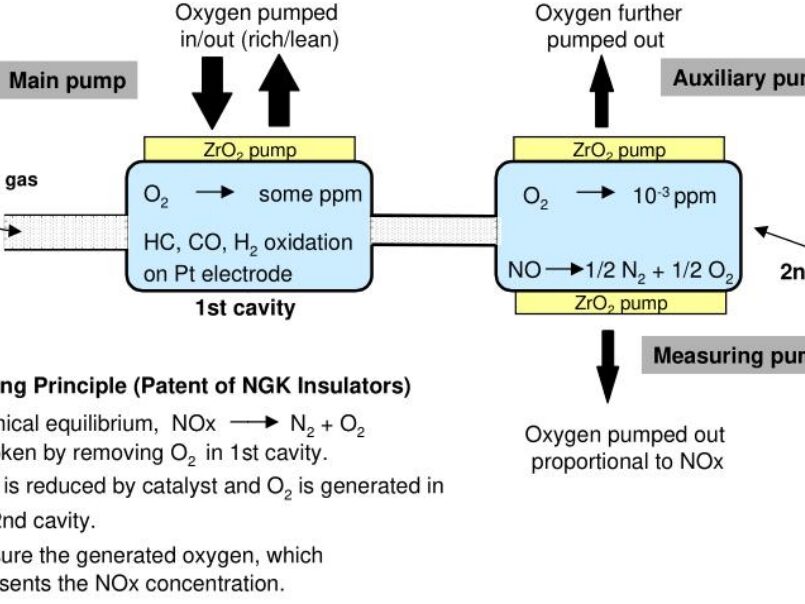

How does the Nox sensor work?

This ceramic sensor is based on a yttrium-doped zirconia electrolyte that measures the oxygen concentration in the exhaust gas entering the diffusion barrier and reaching the first chamber.

Spend. in the first chamber by applying a constant voltage V0 to the main pump motor (P+, P-). The oxygen concentration in the chamber is accompanied by a pump

The current IP0 is drawn away, leaving a small amount of oxygen concentration. IP0 is directly proportional to the amount of oxygen entering the chamber and the amount of oxygen pumped away through the electrolyte

Compare. Other exhaust gas components like HC, CO, H2, etc. are oxidized on the pump electrode made of Pt. Small amounts of oxygen and NOx to be tested

The gas enters the second chamber, where the remaining oxygen is completely removed by the auxiliary pump and reacts on the measuring electrode

(NO↔ N2+O2), the generated oxygen is gradually pumped away by the measuring pump, and the balance of the reaction is broken, resulting in all NO

Decomposed and pumped away, the resulting IP2 represents the concentration of NOx in the exhaust gas.

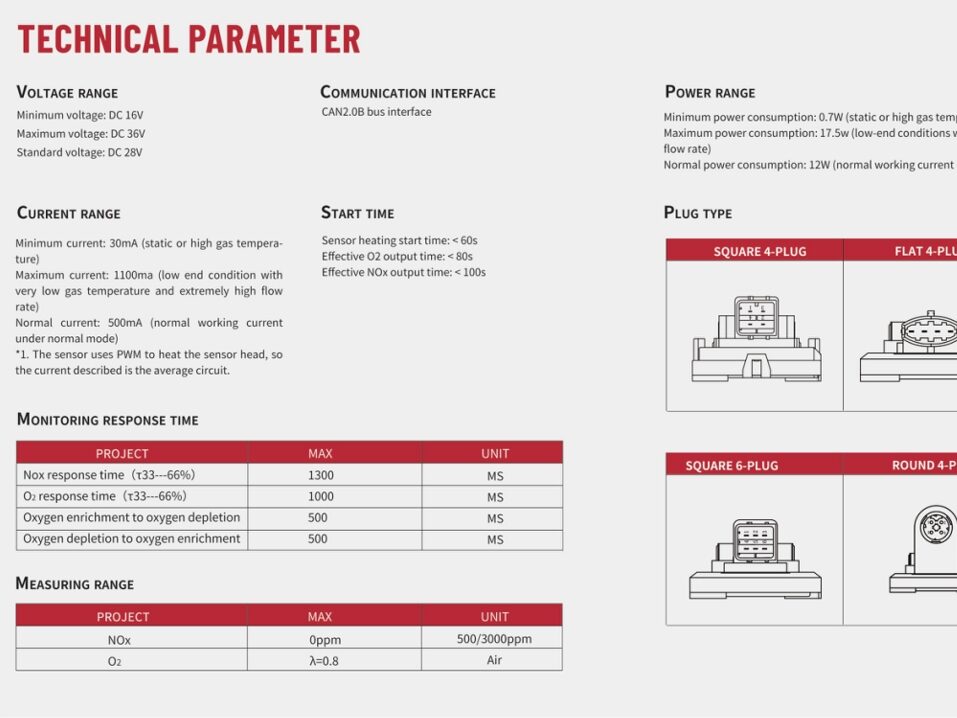

The electronic control unit provides heating power control for heating the sensing element to an operating temperature. All pump unit work

The conditions determine the concentration of NOx. The air-fuel ratio, oxygen concentration, and nitrogen and oxygen concentration signals are transmitted to the DCU (SCR) through the CAN bus.

Control system), used to control the injection volume of urea.

Features of our NOxsensor

★Reliability tests meet the standard GB/5772-2010, GB17691-2005, JB/T51184-2000

★ Efficiency tests meet the standard EPS200 , EPS708 , EPS815

★Programmable, content can be replaced

Programmable NOx sensor

What is the difference between our products and market products?

Nox sensor test and programmable demonstration video

PRODUCTION MANAGEMENT

- The core equipment consists of the world’s top equipment, product consistency is guaranteed.

- BG is developing, utilizing and optimizing its manufacturing, procurement and engineering design capabilities to the global level.

- Rapid and flexible product development and implementation of lean production process from raw materials to finished products.

Service Entrance

Choose Best Growth and grow safely your business

Contact with us , to get your specific marketing solution

BEST GROWTH

Copyright © 2023, best-growth IE Co, Ltd. All rights reserved.